CLEAN BENCHES

Maytech Clean Benches are an essential tool for creating a sterile work environment in laboratory and manufacturing settings. Our Clean Benches use HEPA (High Efficiency Particulate Air) filters to purify the air and remove contaminants, providing a clean and safe working environment.

We offer Clean Benches in various sizes and configurations to meet the specific needs of different applications. The Clean Bench body is made of stainless steel, which is easy to clean and provides a durable surface for many years of use.

Our Clean Benches can be either vertical or horizontal, depending on the application. We also offer options such as UV lighting for further sterilization, ensuring the highest level of cleanliness possible.

In summary, our Clean Benches provide an efficient and customizable solution for creating a sterile work environment in laboratory and manufacturing settings. With our range of options and features, we can design a Clean Bench that meets the specific needs of your industry and application. Trust us to deliver high-quality Clean Benches that meet your requirements for a safe and sterile workspace.

Features:

- Our Clean Benches use HEPA (High Efficiency Particulate Air) filters to purify the air and remove contaminants, providing a clean and safe working environment.

- We offer Clean Benches in various sizes and configurations to meet the specific needs of different applications.

- The Clean Bench body is made of stainless steel, which is easy to clean and provides a durable surface for many years of use.

- Our Clean Benches can be either vertical or horizontal, depending on the application.

- We offer options such as UV lighting for further sterilization, ensuring the highest level of cleanliness possible.

Product Images:

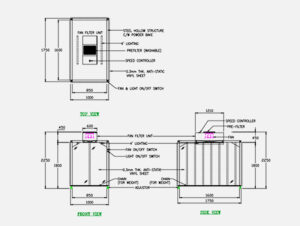

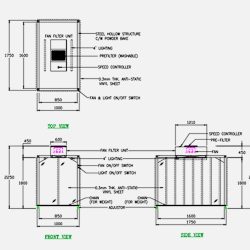

CLEAN BOOTH

Maytech Clean Booth is a device that provides a controlled clean environment, typically used in the production and manufacturing processes of industries such as semiconductors, optoelectronics, and medical devices. The Clean Booth filters harmful substances such as dust and bacteria from the air, ensuring a clean production environment and guaranteeing the quality and performance of the product.

Our Clean Booths use advanced air filtration technology and can be customized to different levels of cleanliness according to customer needs, achieving ISO 5-8 levels. We also offer a variety of specifications and models of Clean Booths to meet different production scenarios and needs.

Our Clean Booths not only have excellent filtering performance but also have practical features such as intelligent control systems, lighting systems, and anti-static properties to meet customers’ personalized needs. We also provide comprehensive pre-sales consultation and after-sales services to ensure customer satisfaction.

Our Clean Booths are widely used in industries such as semiconductors, optoelectronics, and medical devices and are highly praised by customers. If you would like to learn more about our Clean Booth products and services, please feel free to contact our customer service team. We will provide you with professional solutions.

Features:

- Clean Booths create a clean area within a large space.

- Customizable to meet cleanroom standards from ISO Class 5 to ISO Class 7.

- Made of powder-coated cold steel or stainless steel for durability.

- Includes Fan Filter Unit and HEPA/ ULPA filter installed on top for efficient air filtration.

- Wall materials available in PVC sheet, anti-static PVC curtain, acrylic, and other options.

- Optional UV light for enhanced cleanliness.

- Air velocity is adjustable between 0.3m/s – 0.5m/s.

- Modular design makes Clean Booths easy to install and set up on-site.

Product Images:

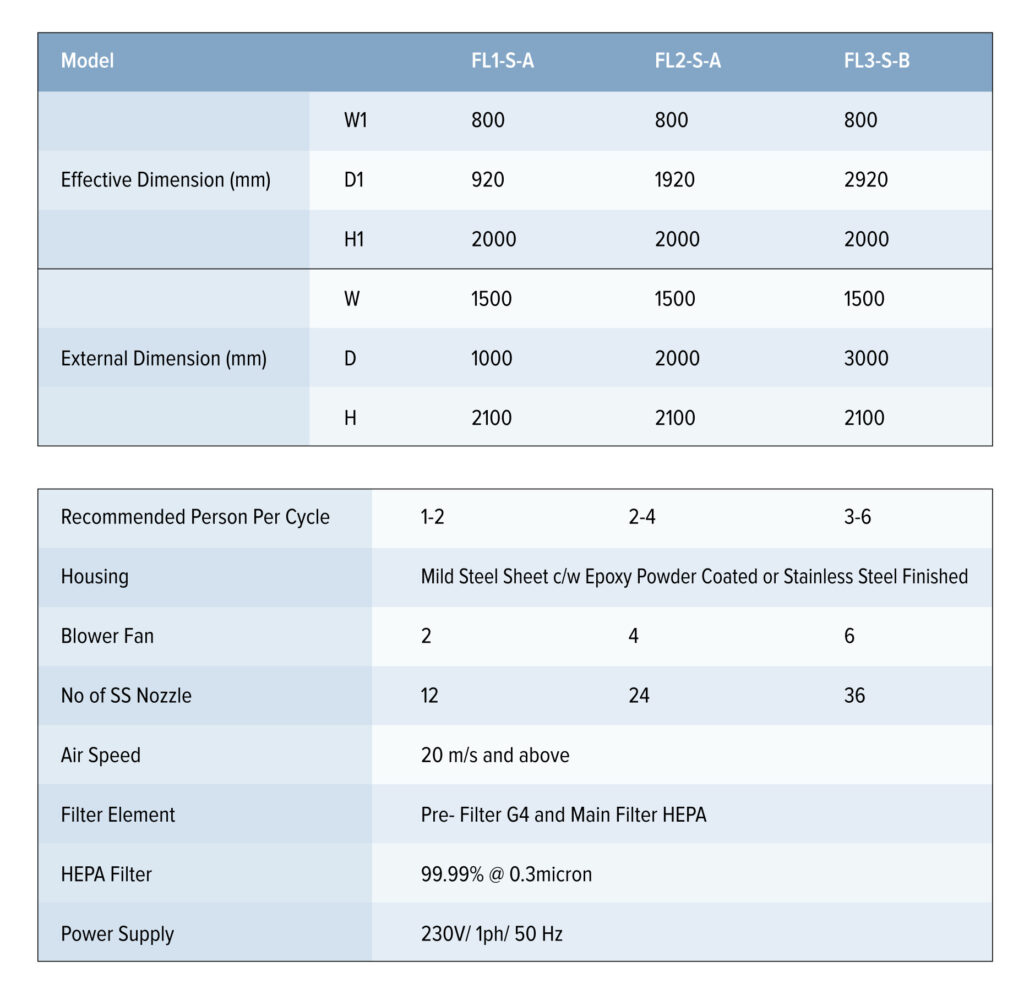

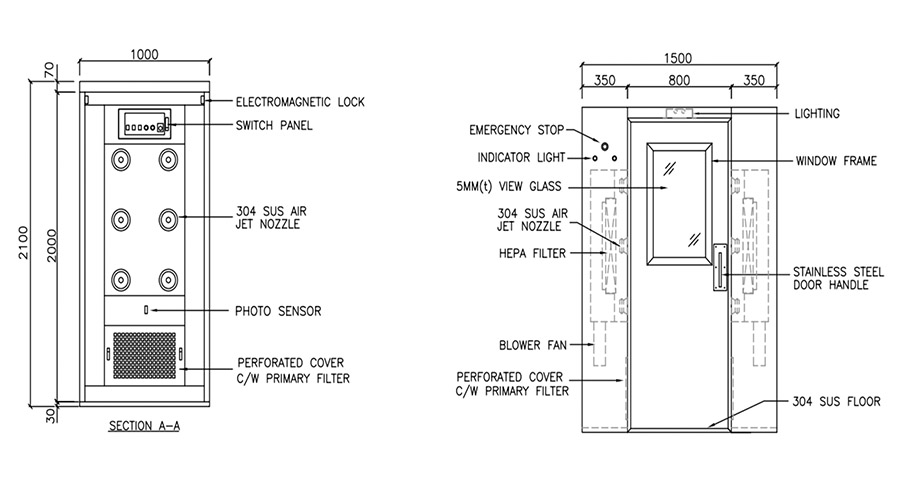

CLEANROOM AIR SHOWER

Maytech Cleanroom air shower is an efficient and reliable air shower device widely used in cleanrooms, laboratories, pharmaceutical factories, electronics factories, food factories, and other places to remove particles and microorganisms from the surfaces of personnel and materials, ensuring the cleanliness and hygiene level of the production environment. Our company provides various models and sizes of air showers to meet different needs and occasions.

Maytech air showers use advanced high-efficiency filters and high-pressure nozzles to quickly remove dust, bacteria, and other particles from the surfaces of personnel and materials, ensuring the cleanliness of the air shower. Its unique air shower design can effectively prevent pollutants from entering the clean area, ensuring that the clean area always maintains a clean and stable airflow state.

Our Cleanroom air showers not only have excellent filtering performance but also have practical features such as intelligent control systems, lighting systems, and anti-static properties to meet customers’ personalized needs. We also provide comprehensive pre-sales consultation and after-sales services to ensure customer satisfaction.

Maytech air showers have the following advantages:

High-efficiency filter: Using a high-efficiency filter, it can filter particles and bacteria above 0.3 microns, ensuring the cleanliness of the air shower.

High-pressure nozzle: Using a high-pressure nozzle, it can quickly remove dust, bacteria, and other particles from the surfaces of personnel and materials.

Unique air shower design: Using a unique air shower design, it can effectively prevent pollutants from entering the clean area, ensuring that the clean area always maintains a clean and stable airflow state.

Customizability: We can provide air showers of different sizes, models, and functions according to customer needs.

Product Images:

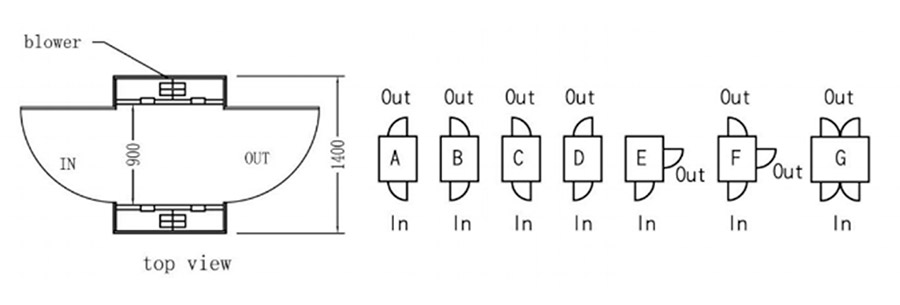

Air Shower Types:

BAG-IN BAG-OUT (BIBO) SYSTEM

Bag-in Bag-out (BIBO) system is developed for nuclear industry to handle potential radioactive airflows.

This technology later applied to the pharmaceutical and microbiological industries to handle raw product and pathogens that require essential containment.

Our Bag-in Bag-out (BIBO) systems not only have excellent filtering performance but also have practical features such as intelligent control systems, lighting systems, and anti-static properties to meet customers’ personalized needs. We also provide comprehensive pre-sales consultation and after-sales services to ensure customer satisfaction.

BIBO is normally installed for air exhaust/ discharge system to prevent leakage of harmful contaminants.

Safe change air filtration is a process to safely and fully contain any high risk pathogens within the filter housing that could spread disease or viruses.

The installation, replacement and testing of filter are done using a PVC bag to prevent the contact between contaminated air filter, the operator and the environment. This can ensure the safety of operators and its surrounding.

Applications:

- Nuclear Power Plant

- Hospital & Pharmaceutical Plant

- Microbiological lab

Bio Safety Requirement (GMP and WHO Standards & Guidelines)

- All BSL3 and BSL4 classification laboratories require the extract exhaust air to be filtered using HEPA filters.

- All HEPA filtration should be located as close as possible to the containment barrier and include provisions for BIBO filter replacement.

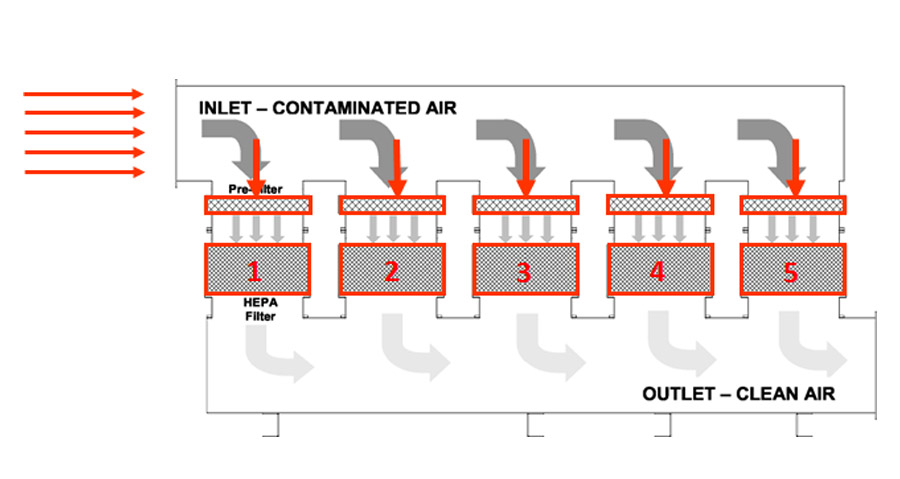

Working Principle

- Air is extracted from the contaminated areas and drawn into the BIBO containment system where the air is distributed evenly through the 5 sets of filters.

- The first filters are called Pre-filters, these filters trap all the larger particles of dust.

- Then the air passes through HEPA filters that are available in different grades to suit the application.

- Once the air has passed through the filters it is then clean enough to be returned to the outside environment.

Control of Quality

BIBO to be 100% testing according to ASME N509/N510 standard. BIBO shall undergoes a pressure testing of 2500Pa during production to ensure leakage rate is within the safety standard.

On-site in situ testing and filter testing (including PAO leak test) can also be performed upon request by customer. Volumetric PAO testing is commonly done at site to ensure the performance of air filter.

BIBO Systems are normally operated in negative pressure, this gives the added protection of containment in the event of any leakage caused by damage. However, it is recommended to repeat the pressure testing before connecting to the extract ductwork.

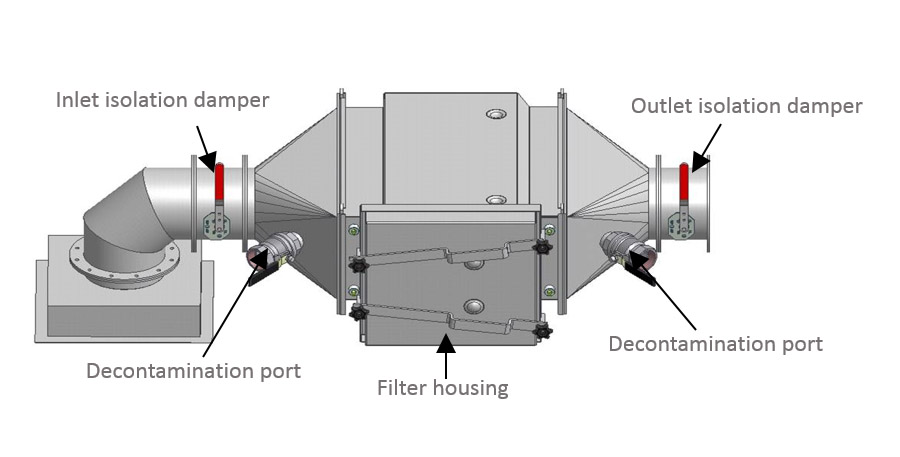

Material & Structure

- Maytech BIBO is available with modular assembly method. It can be designed and assembled based on air flow and available space. BIBO can be designed in vertical or horizontal installation configuration depend on client requirement.

- To guarantee the total security essential with these BIBO systems the filter housing must be a fully welded construction and manufactured under ISO quality standards.

- To comply with the ever increasing corrosive properties of fumigation media used, stainless steel is strongly recommended. However, powder coated frame is available as well.

- Zero leakage isolation damper is recommended to be used to ensure the product stability.

- Pressure gauge is installed to indicate the pressure drop across the filters. It alerts the change interval of the filters.

- Decontamination before any filter change is essential. Normally, the filter and BIBO housing is decontaminated using either Formaldehyde or Vaporized Hydrogen Peroxide (VHP) through the port. The inlet and outlet isolation dampers are closed and the fumigation media circulated around the BIBO housing and HEPA filter for the specified time.

Safe Change Procedure

Step 1:

The Bag In Bag Out design uses special PVC bags that seal onto the housing allowing the contaminated filter to be drawn into the bag and sealed closed.

Step 2:

A clean filter is placed inside a new safe change bag and the open end placed over the filter housing bag ring.

Step 3:

The clean filter is then positioned into the housing and clamped against the sealing face.

Step 4:

The remaining piece of the dirty bag is moved to the end of the new bag, sealed and removed.

Step 5:

The new bag is folded up into the cover area ready for the next filter change.

At no time is the filter or inner surface of the housing exposed to the clean environment during this procedure.

PASS-BOX

A Pass-through Box is a widely used equipment in environments such as cleanrooms, typically consisting of a wall-mounted unit between two rooms that are isolated from each other. Pass-through boxes allow items to be transferred between two rooms of differing cleanliness levels while preventing cross-contamination. This equipment typically consists of two doors, filters, and ultraviolet lights to ensure the air quality during the transfer of items.

Applications:

- Nuclear Power Plant

- Safety Food

- Microbiological lab

- Hospital & Pharmaceutical Plant

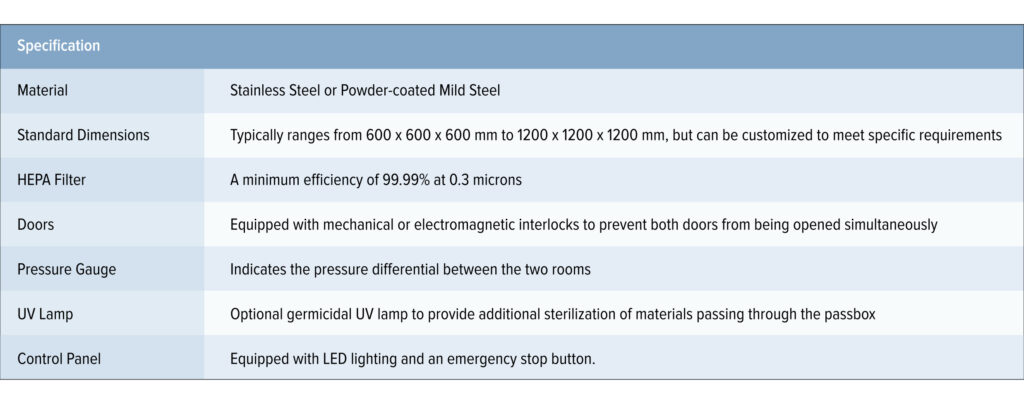

Static Pass-box

Maytech static passbox is a cleanroom equipment used to transfer small items between cleanrooms or clean areas while minimizing contamination. It typically consists of a stainless steel or powder-coated mild steel enclosure with two doors, one on either side, and a HEPA filter to provide high-efficiency air filtration. The doors are equipped with mechanical or electromagnetic interlocks to prevent both doors from being opened simultaneously, which helps maintain the integrity of the clean environment.

Static passboxes are available in various standard dimensions, but can also be customized to meet specific requirements. They are often used in pharmaceutical, biotech, and semiconductor manufacturing industries, as well as in research labs and hospitals.

In addition to the HEPA filter, some static passboxes may also include optional features such as a pressure gauge to monitor the pressure differential between the two rooms, a germicidal UV lamp to provide additional sterilization, and a control panel with LED lighting and an emergency stop button.

Note that the exact specifications can vary depending on the specific manufacturer and model of the static passbox. It’s always recommended to check with the manufacturer for the most up-to-date and accurate specifications for the model you are interested in.

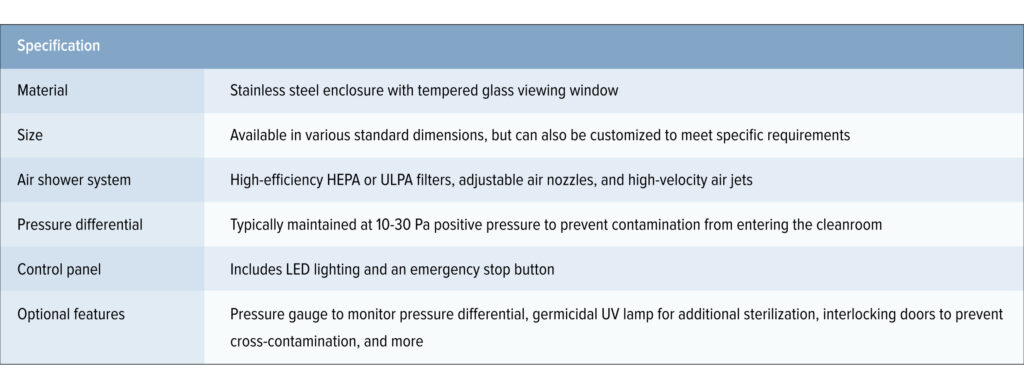

Active Pass-Box

Maytech active passbox, also known as a dynamic passbox, is a type of cleanroom equipment used to transfer larger items between two or more cleanrooms or clean areas. Unlike a static passbox, an active passbox uses an air shower system to provide high-efficiency air filtration and decontamination of materials passing through the unit.

An active passbox typically consists of a stainless steel enclosure with a door on one side and an air shower system on the other side. The air shower system typically includes high-efficiency HEPA or ULPA filters, adjustable air nozzles, and high-velocity air jets to remove and capture airborne particles from the surface of items entering the passbox.

Active passboxes are often used in industries such as pharmaceuticals, biotechnology, and electronics manufacturing, as well as in research labs and hospitals. They are available in various standard dimensions, but can also be customized to meet specific requirements.

In addition to the air shower system, some active passboxes may include optional features such as a pressure gauge to monitor the pressure differential between the two rooms, a germicidal UV lamp to provide additional sterilization, and a control panel with LED lighting and an emergency stop button.

Note that the exact specifications can vary depending on the specific manufacturer and model of the dynamic passbox. It’s always recommended to check with the manufacturer for the most up-to-date and accurate specifications for the model you are interested in.